TEST PROCEDURES

VBOX systems are suitable for the following brake test applications:

- ECE regulation 13H Braking

- ECE regulation R90 Brake Pad Testing

- ECE regulation R78 Motorcycle Brake Systems

- FMVSS135 regulation

- ADR 31 regulation

|

- ISO 21994 standard

- SAE J2909

- ABS testing and development

- Tyre testing and development

- AMS testing

|

TYPES OF BRAKE TESTS

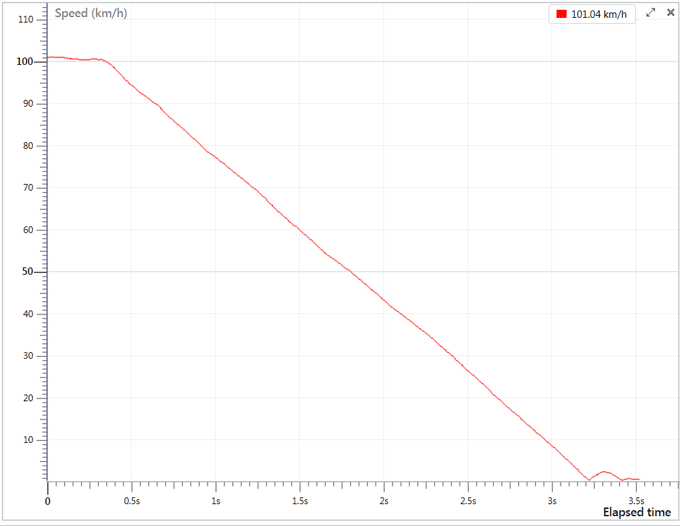

Trigger Activated to Standstill

A common test for evaluating the performance of braking systems is the trigger activated test to standstill. A pressure switch is added either to the face of the brake pedal, or into the hydraulic system, to detect when the brake pedal has been pressed. This signals the start of the test and it ends when the vehicle comes to a complete stop. The distance between these two points is then calculated to measure braking performance.

As this test starts when the pedal is pressed, it measures both the response of the braking system, as well as the performance of the tyre, brake pads, discs and other components.

In a trigger activated test, it is critical to accurately capture the point at which the brake pedal is pressed because the vehicle is usually traveling quite fast at this point. The VBOX 3i uses a very sophisticated method which measures this to within 25 billionth of a second!

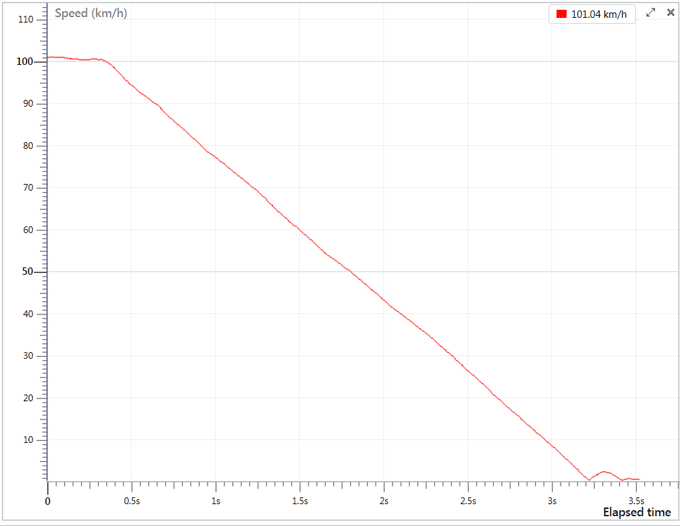

Between Speeds

Another popular assessment of performance is the brake test between two different speeds. These speeds are usually chosen in order to eliminate the response time of the braking system, which is usually during the more linear part of the deceleration period.

These tests are useful for analysing the performance of tyres due to the consistency of braking distances recorded.

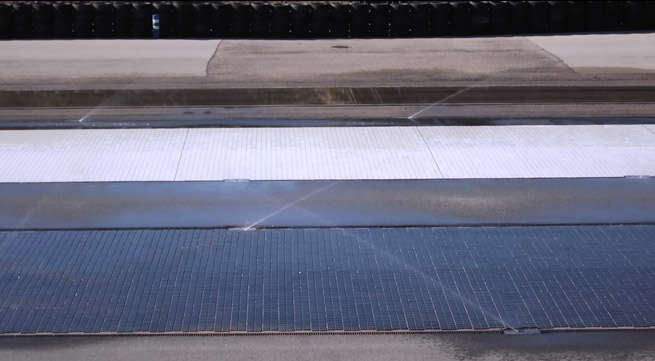

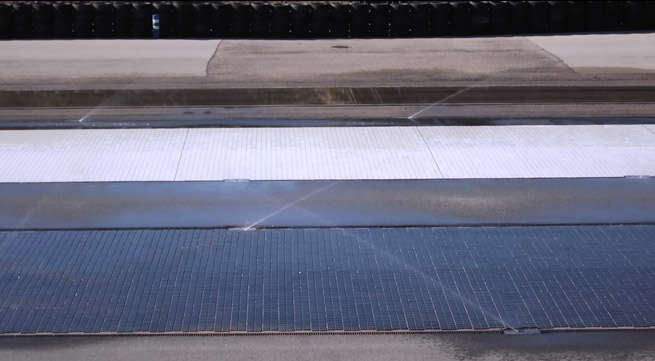

‘Split mu’

This involves both sides of the vehicle running on different surfaces to determine how the braking system copes with different levels of traction. This test also allows engineers to analyse the stability of the vehicle.

Brake and turn

This comprises of the vehicle performing a brake test during a turn. This helps engineers to determine the stability of the vehicle during such a manoeuvre.

ECE R90 BRAKE PAD TESTING

ECE R90 stipulates that all brake pads and linings manufactured and sold within the EU must comply with R90 standards. The test involves comparing the performance of replacement brake pads with those originally fitted.

To comply, the brake pads and linings must be put through speed sensitivity and cold performance equivalence tests and perform to within ±15% of the originals. Pads that have passed will have an “E” mark alongside a number denoting which authority has approved the pad (e.g. UK – ‘E11’).

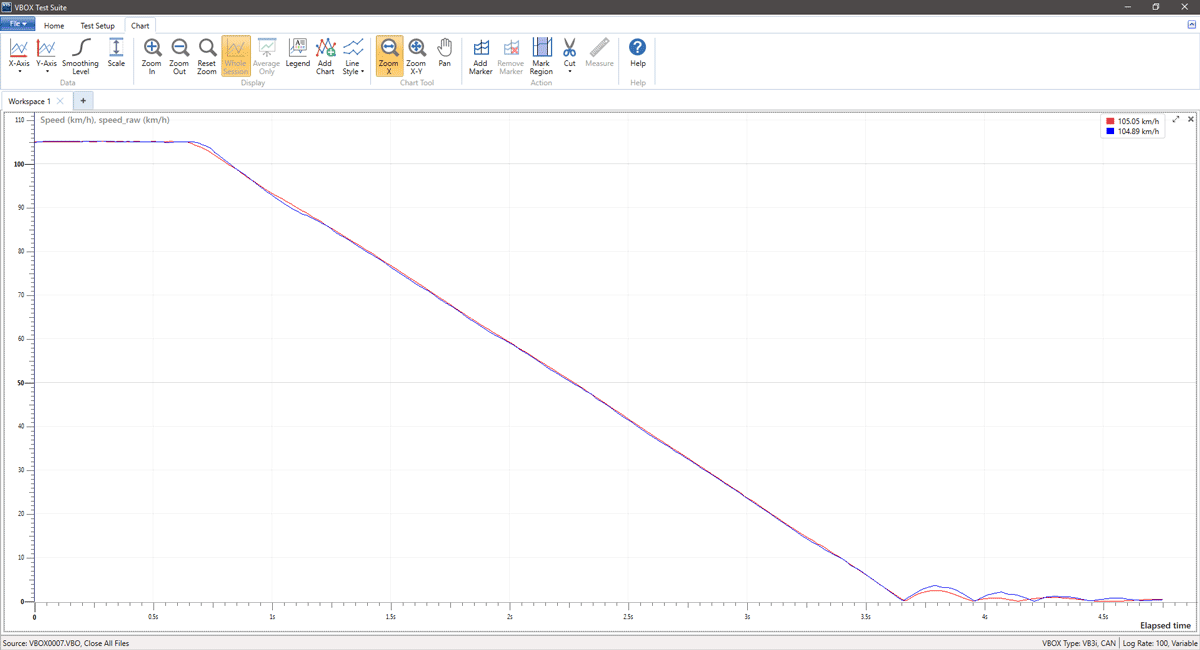

VBOX 3i systems can be used to measure braking distances to within ±2cm accuracy. It calculates parameters such as time, position, velocity, heading, height, vertical velocity and lateral/longitudinal acceleration at 100 samples per second.

VBOX can be used in all four main procedures to satisfy ECE R90 regulations:

- Bedding (burnishing) procedure

- Performance check

- Brake tests (in accordance with Reg. 13 Annex. 4)

- Cold performance equivalence and speed sensitivity tests

In addition to viewing results in real time via a Multi-function Display or Tablet PC, all data parameters captured using a VBOX are recorded using a Compact Flash card. All data can then be viewed using the free VBOX Test Suite software in accessible formats (e.g. graphs, charts).

ECE REGULATION R78 MOTORCYCLE BRAKE SYSTEM

With customer guidance, Racelogic created the VBTS R78 plug-in for homologation testing of motorcycles to the ECE R78 regulation. The regulation specifies the calculation of extra parameters specific to motorcycles, which are now automatically calculated by the software:

- Start Speed

- Braking Time

- Braking distance

- Average Deceleration

- MFDD

- Average deceleration between the 0.5 and 1 second after the brakes have been applied

- Maximum deceleration during the brake test excluding the last 0.5s

- Avg. brake force for the Front and Rear brakes between 80% and 10% of the specified test speed

- Centreline Deviation

ABS TESTING AND DEVELOPMENT

VBOX test equipment enables you to accurately capture individual wheel speed signals, from either CAN or rotary encoders, high dynamic vehicle movement, and the vehicle’s straight line deviation.

BRAKE ASSIST SYSTEM TESTING AND DEVELOPEMENT

VBOX test equipment enables you to capture pedal force and travel sensor outputs via analogue inputs at 500Hz.